Top

iPhone Case

12-28-14

Introduction

I got an iPhone 6 Plus recently. As always it needed a case. There are many cases on the

market ranging from the cosmetic to the waterproof. The cosmetic cases are easily found in

retail stores. The cases that are waterproof and shock proof are difficult to find locally.

There are a lot of cases online that are made of Titanium or are branded "Titanium". Without

elaborating I will just say that I totally don't understand the design purpose of some of

what I see. Also while I could order them online I like to handle them first before making

the purchase.

What better excuse besides wanting to build one is needed?

The following shows my somewhat experimental build of a custom iPhone case.

The first step was to cut a piece of titanium 6 3/8 x 3 1/4 inches. I used a Dremel tool

with a disk grinder to make the cuts. It was slow but effective. I went through three disks

doing these cuts. Next I filed it down smooth and to the measurements I needed.

Next, as titanium is rather stark looking, I laminated walnut veneer. To get more strength

in the edges I set up two layers with grain at 45 degree angles. I set up the finish layer with

grain parallel to the longer dimension of the titanium. I used West Epoxy on the three veneer

layers and let it cure for a day.

Next I cut walnut 1/4" square section to make the edges. I sized the opening carefully to

accomodate the titanium sheet in a snug fit but I did not install the titanium yet. After the

rectangle cured I cut away the excess veneer. Finally I glued in the titanium with just enough

3M 5200 to coat the back of the titanium. I weighed it down with enough force to hold it tightly

against the veneer until it cured. There was just a small amount of squeeze out which I trimmed

away.

Tansy is helping out with the build.

Next I make the back. As this doesn't require as much knock resistance I used a sheet of 1/8"

sapele. I used the completed front to trace the outline for the back. As with the front I used

1/4 walnut square section.

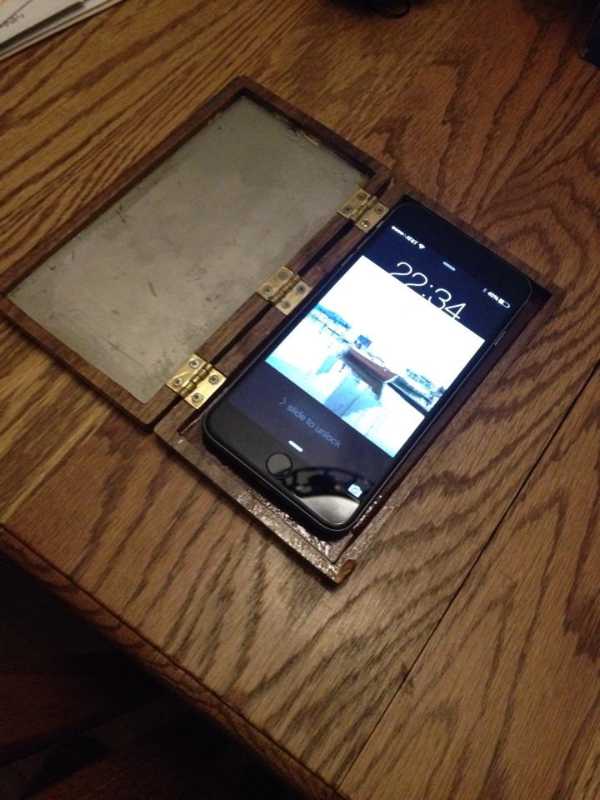

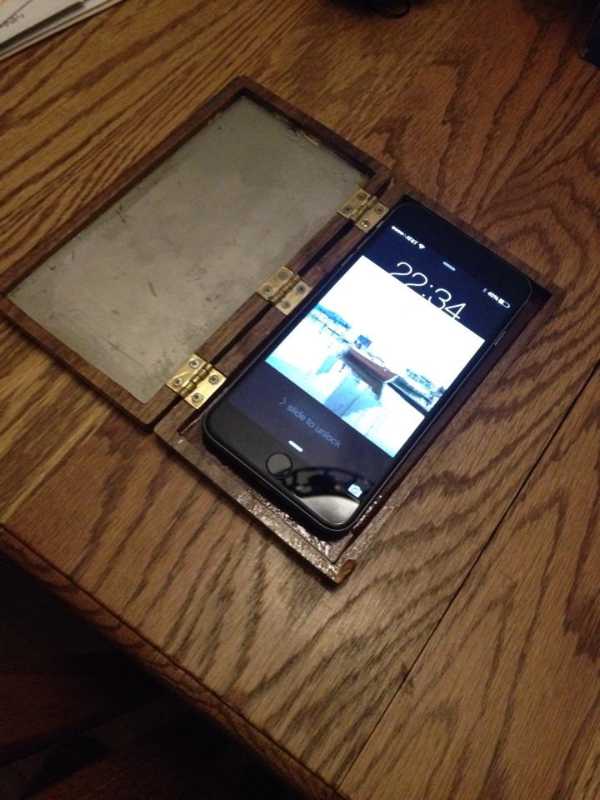

Here is the nearly complete case. I mounted three small hinges. I very carefully sized the depth and diameter of the

holes for the hinge screws. Instead of cutting slots to recess the hinges I built the border up with more walnut veneer.

The veneer was almost as thick as the hinges so it worked out well.

Here is the finished case. I sanded the corners slightly round and applied

three coats of thinned Epifanes varnish.

I mounted the iPhone with small squares of sticky velcro. Unlike with the iPhone

4s the velcro sticks tenaciously to the back of the phone.

Using

This box is only slightly larger than my circa 1996 Rhino Skin Titanium box. After

using it for a few weeks it works out well. But the most glaring deficiency is the

lack of a camera hole. I looked at putting one in but the backwash of light from the

edges of the hole will fog the picture up. I may go ahead and do it though and paint

the edges of the hole black. Alternatively I may make the back hinged down so it will

not have that problem at all. There is plenty of room inside for the iPhone so I can

try out some ideas.

The three hinges have held up so far without any sign of coming loose.

I'm completely happy with the way the front turned out so I won't change it any.